Case Study: Machine Communication System (MCS) Implementation in an Aerospace Machine Shop

Introduction

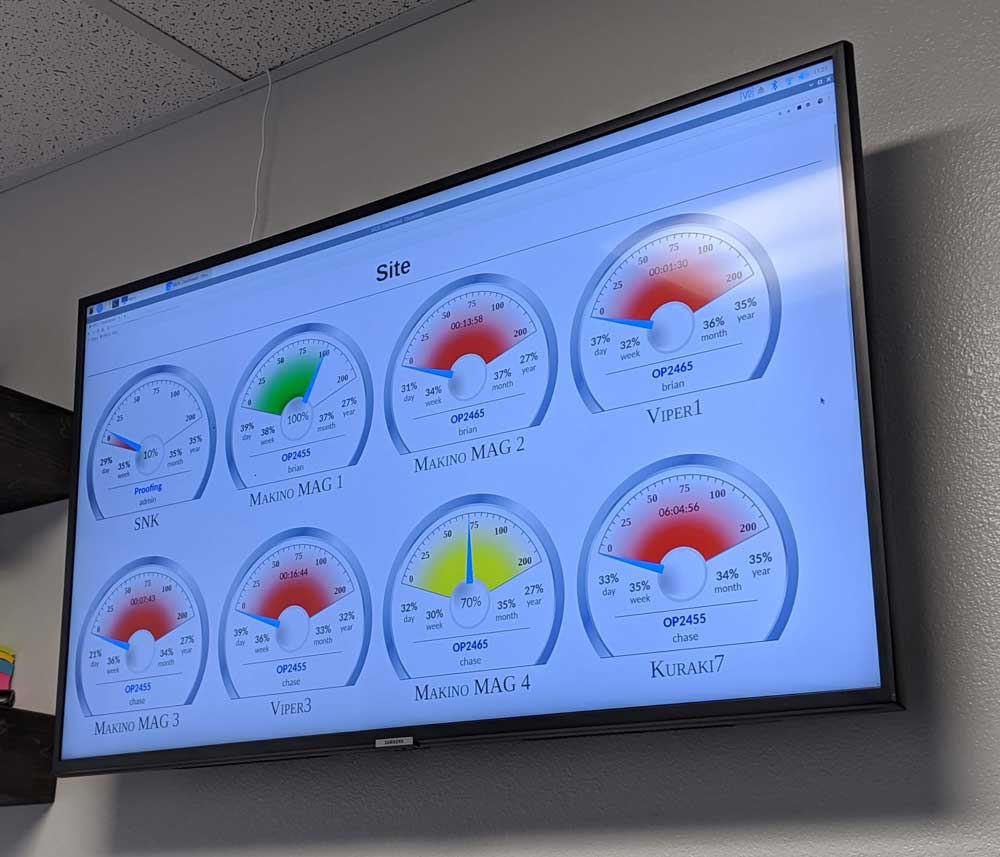

NC Software Solutions deployed the MCS software system at an aerospace manufacturing facility, focusing on a single CNC machine, the GROB G550. The client believed the machine operated “most of the time,” but discrepancies emerged when comparing the required cycle times per process to the actual number of completed processes each day. The client was looking to increase their CNC machine productivity and make more parts without adding machines or shifts. This report covers data gathered over four weeks (June 15 – July 15, 2020). Although only one machine was analyzed (for simplification purposes) in this report, the facility houses a total of 18 machines.

Initial Findings

Monitoring the GROB G550 machine revealed several notable trends:

- The machine rarely operated at the full programmed feed rate of 100%.

- Downtime between run cycles was variable and often excessive.

- Average utilization during shifts was just 39%.

- When running, the machine averaged 87% of the programmed feed rate.

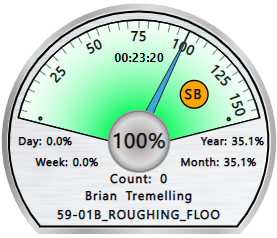

Feed Rate Analysis

Ideally, machine operators should only adjust the programmed feed rate during process validation or under special circumstances. Regular manual adjustments introduce potential for human error and can complicate training for new operators. The parts run during the study had been produced on this machine for several years. Nevertheless, operators frequently adjusted the feed rate, resulting in inconsistent machine settings. During the 129 hours of recorded in-cycle production, roughly 40 hours were lost due to reduced feed rate overrides, effectively reducing productive time to 89 hours and lowering utilization to 27.8%.

Operator Input

Many CNC operators are motivated to prevent machine issues, such as tear-offs, tool breakage, and crashes, and often slow the feed rate to avoid problems. In this case, the feed rate was commonly overridden to 70% or 90% of the programmed rate. After speaking with the machine operator, we learned that an ex-employee had advised running parts at these reduced speeds, but no one else was aware of this recommendation since that individual had left the company two years prior.

Self-Correction

Once MCS displayed real-time data on the machine’s  operation, the reduced speed became apparent. The operator consulted management, who determined that no slowdown was necessary. As a result, productivity on the machine improved by 10-30% immediately. Having real-time data also fostered better communication between operators and programmers. Operators now felt empowered to report concerns, addressing concerns with programmers / management as needed. MCS enabled the precise identification of problematic program blocks, making adjustments painless.

operation, the reduced speed became apparent. The operator consulted management, who determined that no slowdown was necessary. As a result, productivity on the machine improved by 10-30% immediately. Having real-time data also fostered better communication between operators and programmers. Operators now felt empowered to report concerns, addressing concerns with programmers / management as needed. MCS enabled the precise identification of problematic program blocks, making adjustments painless.

Process Intervals

MCS provided insights into intervals of run time and downtime. It became evident that parts typically took about 35 minutes to complete, with new parts beginning roughly an hour later. With the feed rate override reduction issues resolved, attention turned to downtime. The data revealed that, while machines / parts were consistently cycled by operators, occasional anomalies caused the machine to stop for about 20 minutes. The cause was traced to a fixture issue that occasionally required extra setup steps to keep parts secure. After this was addressed, machine availability improved by 20-30 minutes per occurrence, and setup time between all parts decreased.

Additional Recommendations

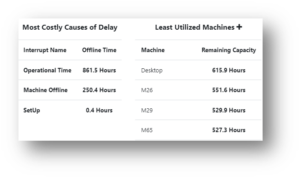

- Continue using MCS to optimize feed rates that are not at 100%, either through programming adjustments or machine settings.

- Continue leveraging MCS to address downtime:

- Identify root causes using built-in interrupts.

- Identify process bottlenecks.

- Track trends in process interruptions.

- Maximize production output relative to costs.

- Use MCS to assess shop capacity:

- Determine when additional work can be accommodated.

- Justify or decline requests for more machines.

- Use data to showcase additional capacity when bidding on potential projects.

- Determine when additional work can be accommodated.

- Display live MCS gauge data in both the office and shop floor.

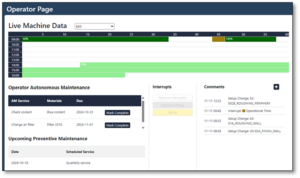

- Utilize the MCS Operator page for operators to log downtime, track parts in production, and add notes or events.

- Implement the MCS maintenance scheduler:

- Schedule operator maintenance tasks (autonomous maintenance).

- Create and manage a preventive maintenance schedule.

- Schedule maintenance based on dates or machine run hours.

Results

The MCS case study on the GROB G550 machine yielded valuable insights over four weeks:

- Feed Rate: Operators had been mistakenly reducing feed rates, increasing production costs on the machine for over a year. Once management became aware, the issue was quickly corrected, establishing a practice of running at the full programmed feed rate.

- In-Cycle vs. Stopped Time: MCS enabled accurate tracking of run and setup times, helping identify delays that had previously gone unnoticed.

- Utilization Data: Before MCS, management overestimated machine utilization, a common error. With MCS, they could see actual utilization and setup times, providing insights to streamline operations.

- Communication: MCS fostered an environment where operators felt comfortable voicing concerns about hardware and software issues. This improved communication enabled timely solutions and enhanced overall efficiency.