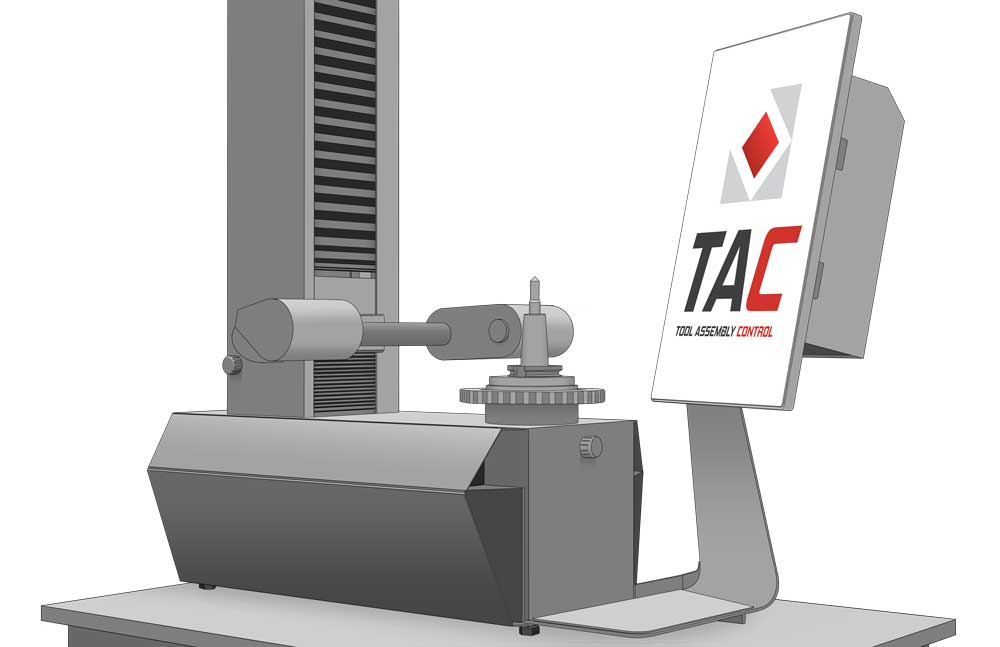

TAC System

Track and automate your CNC tools—allowing you to track tool life and get the most out of each cutter.

TAC monitors tool usage to establish a base-line of the actual utilization life cycle of the tool.

- Track the life of each individual tool

- Establish a baseline of optimal tool usage

- Get the ideal utilization out of each cutting surface

- Available as a stand-alone system or as an integrated part of your tool resurfacing process (NCTC)

Cutting Tool Intelligence

Simplicity meets precision. Smart tool management for cost efficiency and extended tool life.

1

Check Components & Build

Tool assembly is checked for proper configuration.

2

Qualify For Use

Preset machine checks configuration and records nomenclature to database staged to machine for use.

3

Load in Machine

Loaded into machine tool carousel. Offset loading not required.

4

Verify Correct Tool is Loaded

Tool data is automatically loaded into control.

5

Utilize Full Life of Tooling

Each use of tool updates tool life to database. Move to as many machines as desired until tool life has expired.

Repeat

Please Note

Once tool life is expired, machine will not allow re-use.

It Starts At Assembly

TAC smoothly manages tool assemblies through their complete lifecycle. With a user-friendly interface, the system ensures the assembly always conforms to the nomenclature specified in the set-up sheet. No more setup errors.

Tool Data Recording

TAC integrates the use of a tool setter to automatically record the exact measurements of each assembly into a database which is matched up to each assembly. This process is automatic and eliminates human input errors.

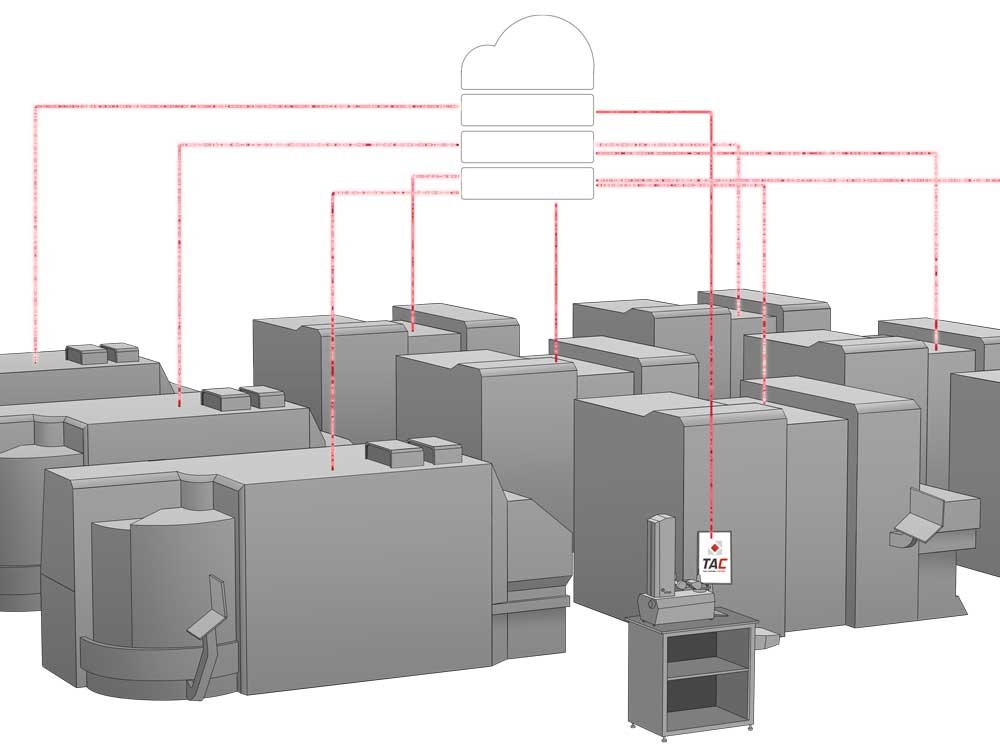

Data Synchronization

Within the machine environment, only the tool setter data is used to load the machine tool offsets. TAC also collects the run time to closely monitor tool life. Setup time is reduced, and errors are eliminated, by Operators only needing to load the assembly in the machine.

Full Control of Cutting-Edge Data

TAC offers a dynamic, real-time tool assembly data management system that is not limited to a single machine. Move tool assemblies to different machines while maintaining complete control of tool life and inventory. Efficiently share limited use assemblies to reduce mulitple low use builds.

1. Maximizing Tool Life Efficiency

2. Eradicating Offset Errors

3. Eliminating Human-Induced Tool Loading Errors

4. Eliminating Tool Assembly Mistakes

Why choose us

What Makes TAC Different?

Ease of Use

Our user-friendly interface means this program truly does take the headache out of automating your factory. State of the art doesn’t have to mean confusing or complicated when you choose TAC for your Industry 4.0 factory. TAC is available as a standalone system or can be integrated with NC Tool Comp for a complete tool resurfacing process.

Machine Learning

Establish a baseline of optimal tool life and adjust real-time to ensure you’re getting the most out of each cutter. See in real time which tool is being used at which machine and the remaining tool life.

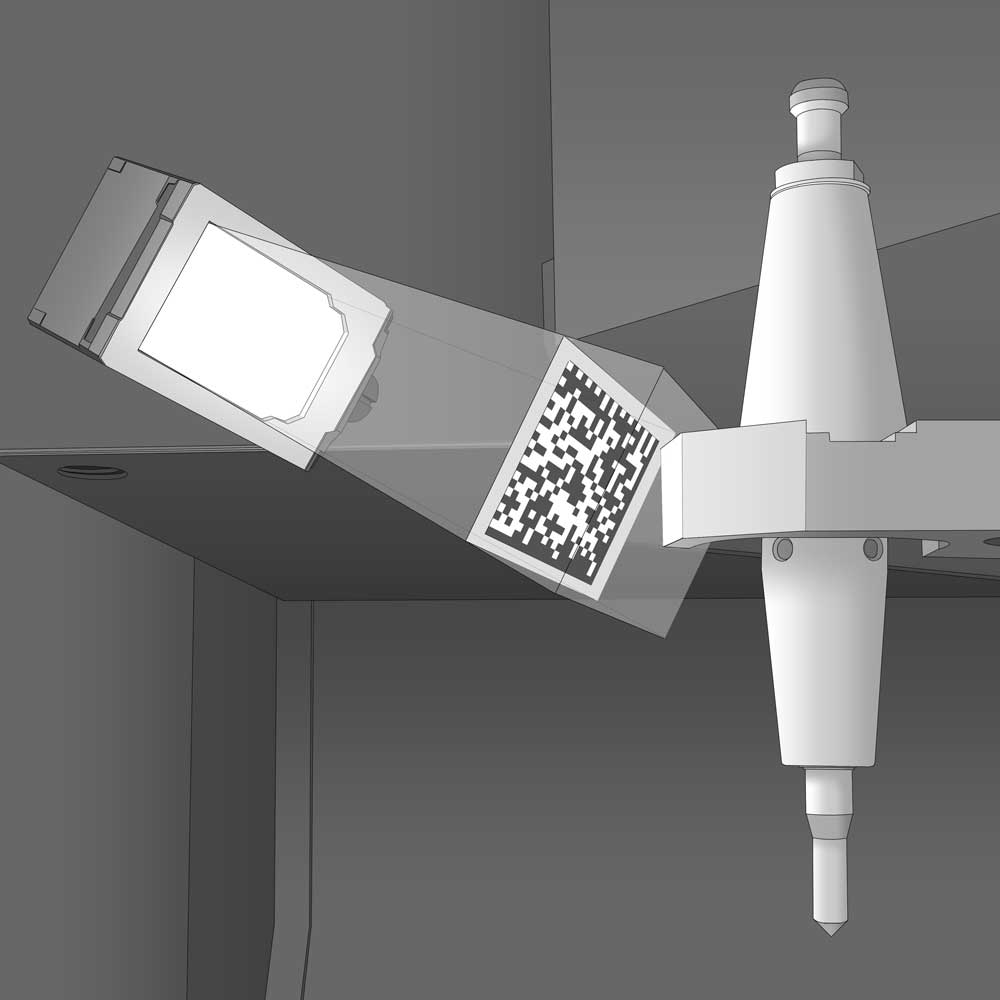

Speed

The TAC system uses QR codes and a database to store and retrieve tool data. This takes less than a second. Other systems use RFID chips that can take up to a minute to retrieve the tool data.

Platform Independent & Versatile

RFID chips require proximity and careful positioning, but QR scanners can be mounted anywhere and scan from great distances. The TAC system is also compatible with all machine types.

Why NCSS Tool Compensation Succeeds Where Others Fail

Cutter Compensation with NC Software’s NCTC saves in overall cutter cost. However, savings alone are not enough if parts are damaged or scraped in the process. Our advanced algorithms deliver a true 3-5 axis compensation for all your machines. Say goodbye to technical complications, operator training issues, and costly errors that have prevented this simple process to lower tool expenditures. NCTC system removes operator involvement, and variation between machine and control combinations. NCTC does not use machine control algorithms so there is no special programming required. Use the G code you currently have, and begin saving on machining costs.