MCS

Machine monitoring of the future - discover process inefficiency and create a lean manufacturing process with just a few clicks.

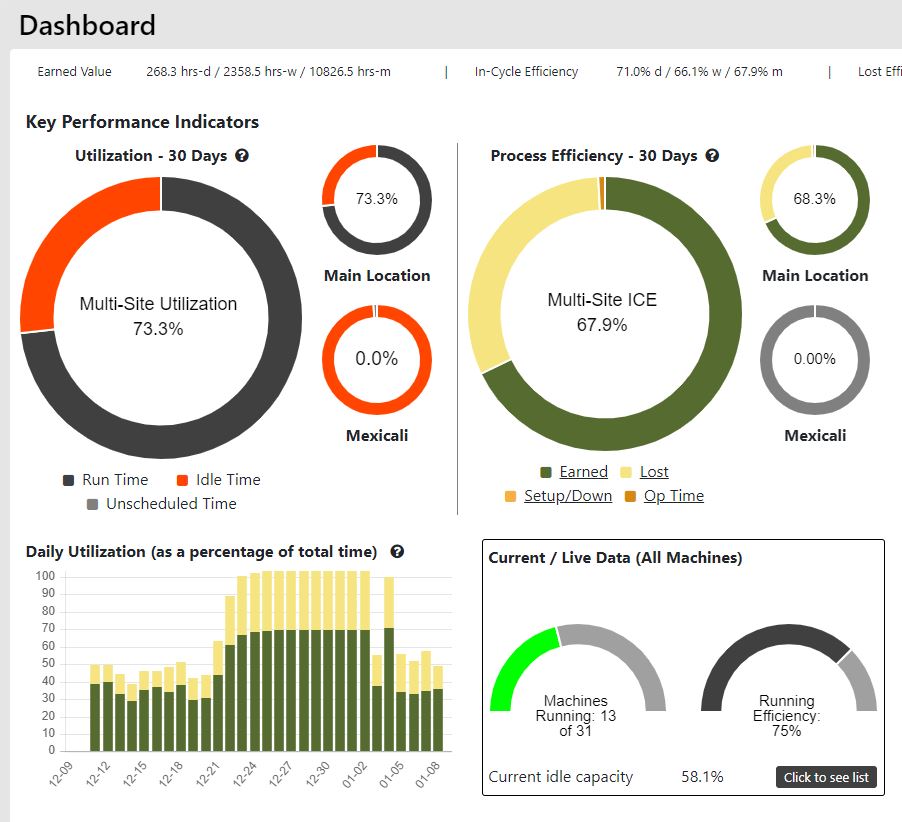

MCS (Machine Communication System) connects to every machine in your factory, tracks what they do 24/7, and stores that data indefinitely. You no longer need to walk around your factory with a clipboard to see what each machine is up to.

Real, Meaningful, Efficient Communication.

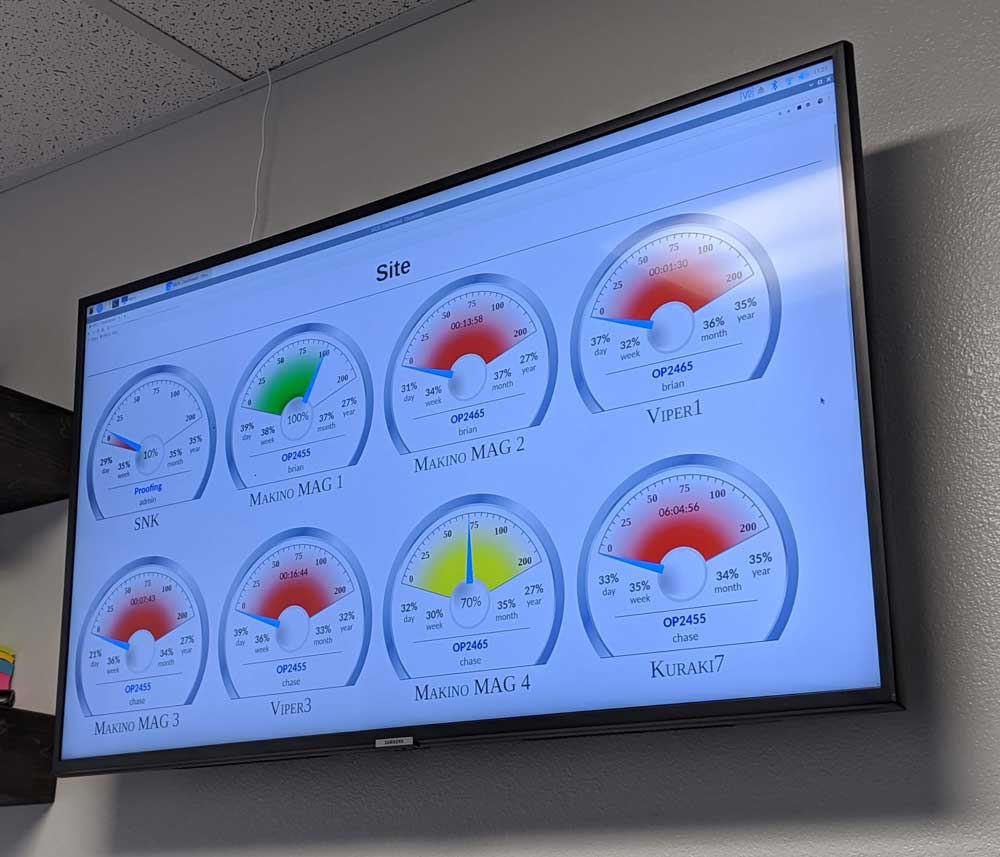

- Monitor CNC machines and CMM’s in real time

- Open architecture: own your data

- Connect to anything, even older machines

- Run lights out and see everything: MCS gives live data so you'll know when your machines are up or down and why. How long is it taking between runs? Are you running to capacity? Do you even know your capacity?

- User Friendly: After MCS is setup in your shop, it usually only takes a short training session for the management and the operators to become a fully integrated part of your process.

MCS provides deeper insights than what you can see by simply looking.

Get live data so you’ll know when your machines are up or down and why. How long is it taking between runs? Are you running to capacity? Do you even know your capacity? Get the most out of each machine with MCS.

The best part is, it’s completely web based. Once MCS is installed in your facility, you can log in from any computer on the network and see reports, charts, and productivity in real time. You can even schedule and manage maintenance.

MCS Return on Investment (ROI) & Immediate Impact

- The existing efficiency of your operation.

- Your ability and willingness to address identified inefficiencies.

While many believe they maintain a highly efficient operation, the reality often differs. When asked about their perceived machine runtime as a percentage of scheduled machine time, responses commonly hover around 70-80%. However, unless constantly running extended processes with quick turnarounds, actual rates likely fall within the 30-40% range. Increase the output of your shop by as much as 20% or more without adding to the payroll by using MCS.

Immediate Impact Factors:

1. Operator Feedrate Override:

2. Machine Availability:

3. Interrupt or Stoppage Events:

Immediate Impact: Enhanced production speed, quicker turnarounds, and identification of bottlenecks and process issues.

4. Individual & Group Productivity:

MCS Benefit: Easy comparison of shifts, cells, machines, etc.

5. Operator Value

Why choose us

What Makes MCS Different?

Ease of Use

Our user-friendly interface means this program truly does take the headache out of automating your factory. State of the art doesn’t have to mean confusing or complicated when you choose MCS for your Industry 4.0 factory.

Platform Independent

You probably don’t have a factory dedicated to one specific machine tool builder. You may be concerned you need a different software for each one. MCS communicates with all of your machines (even CMMs), making this a nonissue for your smart factory.

Open Data Platform

MCS connects a lot of data in real time. It’s your data and can interface with your existing and future processes through open APIs—100% Industry 4.0 compliant.

Tremendous Value

You get a lot of bang for your buck when you choose MCS. The benefits offered far outweigh the costs. View our case studies and see for yourself.